METROBRICK® & the Environment

METROBRICK® strikes a balance between performance, environmental advantages and budget.

Sustainable Design

METROBRICK Thin Brick is manufactured thin – waste in manufacturing is significantly reduced. Unfired and fired scrap is re-processed back into the manufacturing process. All METROBRICK colors contain a minimum of 23% pre-consumer recycled content.

At the construction site, using METROBRICK Thin Brick means less site disturbance when compared to using full brick. A wall system using METROBRICK can also enlarge the building’s floor area and decrease the number of trade contractors. There is also less waste left behind when installing thin brick. A METROBRICK® wall reduces the number of products used and expedites the overall project schedule.

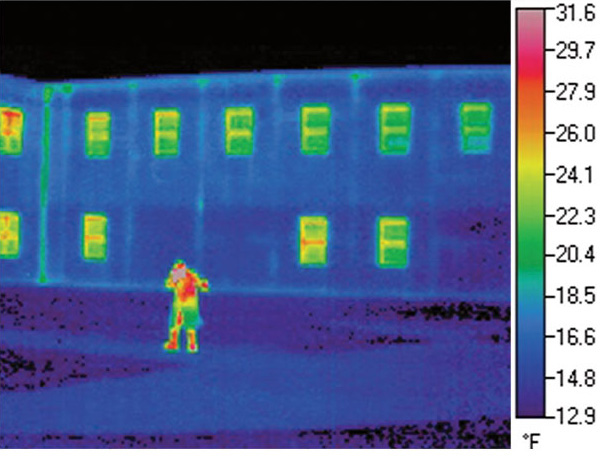

When combined with panel insulation, a METROBRICK wall will increase a project’s R-value – one of many ways METROBRICK Thin Brick can improve a building’s green footprint and help a building attain LEED Certification. All METROBRICK Thin Brick products are third-party certified for multi-attribute sustainability. METROBRICK products also have documentation for a Health Product Declaration and an industry-wide Environmental Product Declaration. METROBRICK has created a Sustainability Product Report that provides all environmental information as a PDF.

Images provided by: Thermomass Insulation Systems

Environmental Advantages

An exterior wall system’s actual performance is critical to a building’s life cycle cost and overall performance. Environmental awareness has forced the design and construction profession to re-evaluate how we use our material resources and has redefined our performance expectations. A thin brick wall system provides a balance between desired performance, environmental advantages and the owner’s budget.

Wall Systems

Precast Construction

Tilt-Up Construction

Field Applied Mortar Set Method

Field Applied Panel Systems

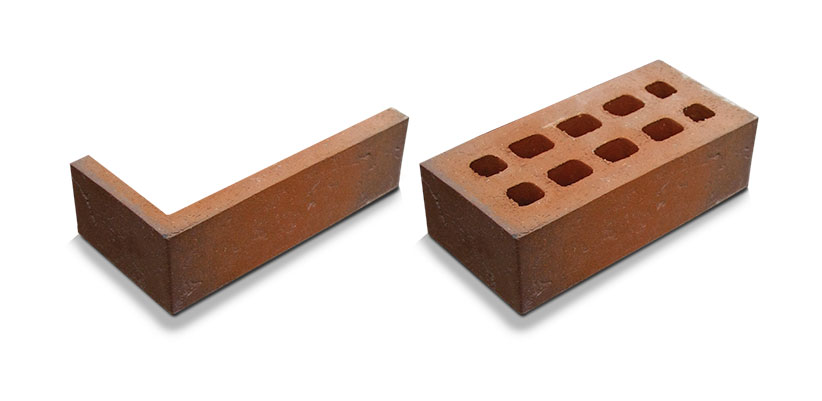

Thin Brick VS Full Brick

The surface and edges of the brick face provide the aesthetic value of a brick wall. Why build an entire full brick cavity wall when a kiln-fired thin brick wall meets the same aesthetic requirements? Building an exterior wall system that includes thin brick provides many environmental advantages over a full brick cavity wall.

Raw Materials

Natural Gas

On The Road

for Insulation

Sustainability

Because METROBRICK® absorptions are much less than full bed brick, spalling and efflorescence are reduced or eliminated. The building facade can basically last forever.

With the thin brick attached to the wall system, minor repairs require only the removal of the affected bricks. Full bed brick building repairs are much more costly and difficult.

Less Site Disturbance

Less Site Disturbance

- The weight of METROBRICK® is engineered in the wall system. Full bed brick requires additional foundation for its support, requiring extra steel and concrete.

- Post-installation clean-up for thin brick is significantly less than full bed brick. When using thin brick, little or no cleaning agents are required at the job site.

- When thin brick is used in precast concrete or tilt-up construction, scaffolding is not needed.

- Panels can be erected from either outside or within the structure’s perimeter, thus allowing more existing trees to remain.