Thin Brick is Green Brick

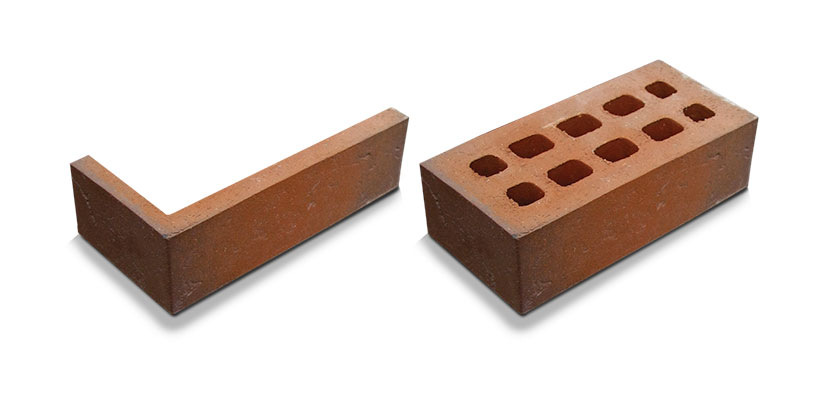

There are many green advantages to building with a wall system that includes thin brick as compared to a full brick cavity wall. Do you really need a full brick to get the aesthetic you want?

Thin Brick VS Full Brick Comparison

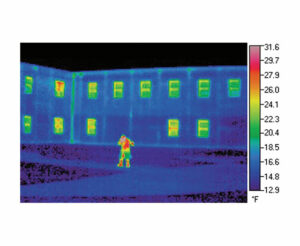

Below is a simple comparison between full bed brick and thin brick. This was created to show some of the energy and resource savings that can be achieved when using a wall system that includes thin brick. This does not include all of the factors that come into play when comparing the complete wall systems. Instead, this is designed as a visual representation to give thought to the potential savings when using a wall system with thin brick.

Thin Brick Weight Advantage

Delivering thin brick can be done on any truck, allowing backhauls. Brick manufacturers usually own full bed brick delivery trucks and haul empty back to the plant. The trucks hauling thin brick can transport over 60,000 bricks compared to full brick, typically carrying only 12,000. In addition, the special cuts and sizes available from METROBRICK® save shipping full pieces to be cut at the job site and the excess discarded in landfills.

- METROBRICK® uses 20% of the clay and shale raw materials used in production.

- Only 20% of the trucking is used to get the raw material from the mine to the factory.

- METROBRICK uses 20% of the amount of fuel (typically natural gas) to fire thin brick.

- Kiln emissions from thin brick are 20% of full bed brick.